King of the Automatics - Technics SL-1600 MK2 Restoration

Back in the early to mid-eighties Technics began revising their core consumer turntable lineup, creating the MK2 series of SL turntables. These were, and often still are, regarded some of the highest quality and most feature rich turntables ever built. While the lineup has largely been overshadowed the monumental success of the MK2 SL-1200, there's one model that's held in nearly as high of regard: the MK2 SL-1600. Here's how I got along with one.

The MK2 SL-1600 succeeds the MK1 and they share the same core principal features; a direct drive motor, a suspended chassis, and a fully automatic mechanism. That's where all the similarities effectively end though, as the SL-1600 MK2 shares nothing else in common with it's predecessor. Honestly, that becomes apparent the second you look at this thing. With it's prominent front mounted control panel and slew of LEDs, you immediately know that this turntable is a completely different animal than the MK1.

What this basically is: it's a fully-automatic SL-1200 MK2. It sports the same style VTA adjustable tonearm and quartz locked direct drive motor as the 1200 MK2, and even the pop-up target light and pitch adjuster - now a small wheel on the front control panel with a KITT-like array of LEDs instead of a full-blown slider. This is a world-renowned DJ deck in the guise of a fancy 1980s home turntable.

This 1600 MK2 was in pretty spectacular condition considering it's age, but it had two major problems. The suspended chassis wasn't working and more importantly, the turntable itself was totally dead. The LEDs on the control panel would light up and respond to inputs, but the turntable wouldn't rotate and the tonearm wouldn't cue or move automatically. Usually, the most common things to go wrong in these decks is a bad tonearm belt or cracked drive gear, but neither of those things should affect the turntable being able to operate manually. The faults here are certainly electrical.

Starting off, I decided to try and figure out why the suspension was effectively non-existent. Looking at the bottom of the turntable, I really couldn't tell what the issue was since all the feet and springs looked intact. So I flipped it upright and pulled the platter off, thinking the issue might be internal.

I was instead greeted with a big fat warning label and three blue tinted screws along with the handful needed to pull the top cover off. The label says to remove the blue screws before use because they're meant to keep the plinth secured during shipping.

"Ah!" I thought. "That's the problem! Whatever nincompoop owned this thing prior never even bothered to pull those screws before using the turntable. Simple fix." And why wouldn't I think that? All I'd have to do is undo those screws and problem solved, right?

Wrong.

Turns out there are supposed to be two red screws in the back of the turntable that link the suspended base to the plinth, and mine were missing. This differs from the MK1 where the feet screws were what joined the two halves together. On the MK2, only the front feet serve that same purpose. The rear feet just screw directly into the plinth and bypass the suspension pieces completely. I replaced the screws with some rough equivalents from the hardware store that I still had to cut down to size. The originals appeared to be metric sheet metal threads of sorts, so while my imperial replacements weren't quite the correct fit, they were snug enough when tightened down.

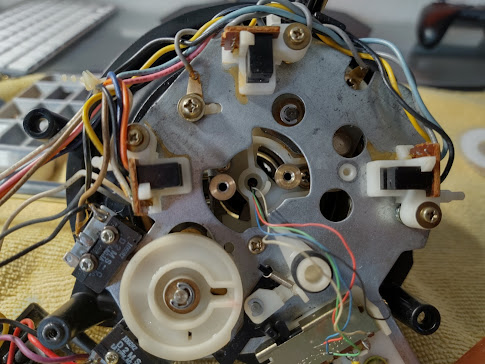

With the suspension sorted, it was now time to dive into the internals of the MK2. Pop the top cover off and you're greeted with a mind-bending slew of PCBs. If the MK1 was engineered like a Volkswagen Beetle, this thing is a Bentley Continental. Having just come off repairing the insanity that was the Sharp VZ-3000 though, this thing was a breath of fresh air. A fresh round of electrolytic capacitors seemed like a good place to start in addressing this thing's electrical woes.

|

| This is just so stupid. |

This all makes diagnosing the turntable's problems quite the pain in the ass. You have to effectively disassemble the entire top half of the turntable, just to be able to see all the PCBs when you reconnect everything for testing. But, considering where Technics wanted to go with this turntable, none of this is too surprising really. This is overengineered excess at it's finest. Sensibility be damned.

You also really want to make sure all this stuff - especially the weirdly shaped cam plate (not pictured) that runs between the array of IR sensors, all goes back on exactly as it was before it was removed. The cam plate determines where the tonearm drops and lifts on a record and if it's not centered exactly as it was before removal, it can drag on other parts of the tonearm mechanism. There isn't any physical feature that helps you center this piece and there's a weird amount of slop in it's placement, so you have to carefully eyeball it and ensure it's not rotating off center before fully tightening everything down.

|

| One of these things does not belong. |

|

| Technics SL-1600MK2 Tonearm Standoff by YALE70 |

With all the internal work done, I threw on some new brackets for a shiny new Reloop dust cover and set to work dialing in the start/stop system - probably the biggest pain in the ass of this entire rebuild. Remember that cam plate I mentioned earlier? It features three adjustable plates that shift the position of the start and stop points. The only problem is that it's very sensitive and stiff, and you have to adjust it using a flathead screwdriver through a quarter-inch wide peep hole on the tonearm base. It takes absolutely forever, even with guidance from the manual. But once it's set, it's staying that way.

The pitch adjuster and target light feel a bit like vestigial leftovers from the 1600 MK2's disc jockeying bones, but it's cool that Technics opted to include them even though it doesn't really need either. And of course, there's the looks. This thing looks sharp as hell being roughly four decades old and you don't see anything nearly this cutting edge looking on the market nowadays. I'm kind of surprised Technics hasn't done a refresh of this beast. We're on generation seven of the SL-1200 now and vinyl is more popular than it has been in decades. How about a SL-1600 MK3? Go nuts.

Comments

Post a Comment